What is Lean Six Sigma?

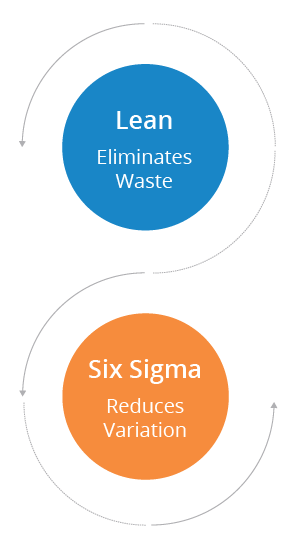

Lean and Six Sigma are two process improvement methodologies which, when used together become extremely powerful business transformation tools.

Businesses all over Ireland are adopting Lean Six Sigma to maximise their organisation’s potential, increase team morale and effectiveness, and minimise waste and downtime.

This article answers the popular question, "What is Lean Six Sigma?", outlines how you can get started with process improvement, and points you in the direction of other helpful articles.

Get the Full Guide Now

You can download and keep our PDF Guide to Lean Six Sigma using the button below.

This 16-page guide includes the information in this article, plus tips for choosing the right course and getting started.

Jump to any part of this article

What is the difference between Lean and Six Sigma?

Lean and Six Sigma are separate methodologies. They originated in different places at different times.

They can be used independently. However, they work so well together and are so often combined that they are more commonly known as "lean six sigma" rather than as separate entities.

A very general description would note that Lean targets waste, while Six Sigma works on reducing variation.

To understand why they are so dynamic together and fully answer the question "What is Lean Six Sigma?", let’s look at them in more detail individually, and then combined.

What is Lean?

Origins of Lean

The concept of “lean manufacturing” and eliminating waste from processes has been around since before the 20th century.

Lean as we know it today was established in the early 1990s, growing from the TPS (Toyota Production System).

Lean started out in the manufacturing sector. It was an approach for streamlining production by eliminating any unnecessary or wasteful elements of the production process.

Today, Lean has travelled expanded far beyond its origins. It is now widely implemented in all sectors of industry and business.

How Does Lean Work?

Lean targets waste, eliminating anything that is “non-value add” from your processes.

Using the 8 wastes as a guiding point, a Lean approach will consider all elements and stages within a process.

This evaluation carefully determines which parts of the process are value-add and essential to quality and productivity, and which elements are considered ‘waste’.

What are the 8 Wastes?

- Defects

- Over-production

- Waiting

- Non-utilised talent

- Transportation

- Inventory

- Motion

- Extra-processing

What is Six Sigma?

Origins of Six Sigma

Six sigma was first introduced within Motorola in 1986.

Its name refers to a statistical concept on the number of defects per million repetitions of a process, or outputs of a product.

Six Sigma is a goal to work towards, the ideal low level of variations and defects per million opportunities (DPMO).

How Does Six Sigma Work?

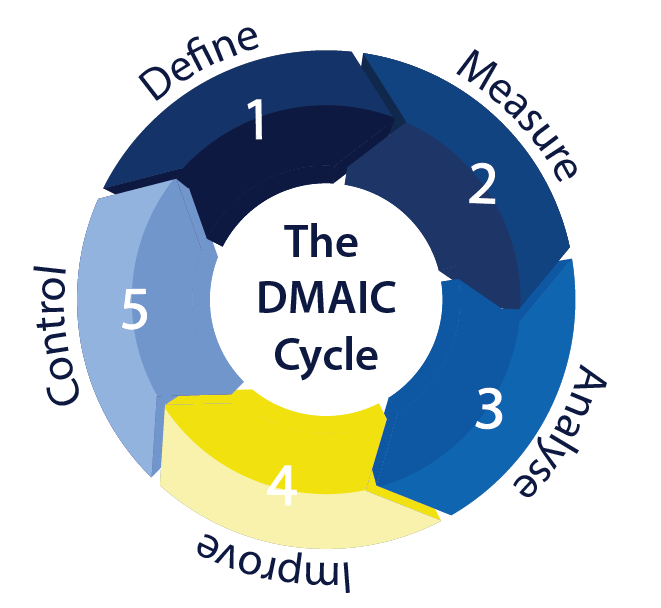

Many refer to Six Sigma as “problem solving”. Six Sigma is used to identify flaws, variations, or defects in a process, and to correct them.

Using the DMAIC Cycle (Define, Measure, Analyse, Implement, Control), a process can be mapped and analysed to identify and resolve issues or flaws.

How do Lean and Six Sigma work together?

You can see how both Lean and Six Sigma can be very effective, even when used alone.

As mentioned above, the two methodologies work so well together that they are almost better known as the combination "Lean Six Sigma" than as standalone methods.

Lean helps you to streamline processes, while Six Sigma works to improve quality by reducing errors or variations. Both methods focus on developing optimally performing processes.

Let’s look at some of the benefits they can achieve when implemented together...

What are the Benefits of Lean Six Sigma?

You will gain so many benefits from correctly implementing Lean Six Sigma.

You can read more in-depth information in our article, Lean Six Sigma Savings and Benefits, but we’ve grouped the highlights below to give you an overview.

- Less Waste, Defects & Variation

- Lower Costs

- More Savings

- Increased Profits

- Improved Efficiency

- Higher Team Engagement

- Better Processes

- Consistent Quality

- Shorter Cycle Times

- Problem Solving Skills

- Faster Lead Times

- Increased Capacity

Lean Six Sigma Belts

Lean six sigma belts help to define roles and establish a structure for process improvement projects and strategy.

There are several different roles. Without a little explanation, it’s impossible to know where you want to channel your energy.

Here's a quick overview of the different belt levels and roles:

White Belt

Has a foundation level of Lean Six Sigma knowledge. Often a recommended level of training for everyone in a business, whether they work on Lean Six Sigma projects or not.Yellow Belt

Has a good understanding of how to apply Lean Six Sigma. Can contribute actively to a process improvement project.Green Belt

Has a strong level of Lean Six Sigma knowledge. Can manage process improvement projects with skill and confidence.Black Belt

Experienced Lean Six Sigma practitioner. Mentors other belt levels and manages process improvement at a cross-functional level.Master Black Belt

Very advanced level of Lean Six Sigma knowledge and experience. Manages process improvement at an organisational, strategic level.Champion

Usually the executive leadership team. Supportive and invested in cultivating a strong process improvement culture across the business.

You can get a more detailed look at the different roles by reading our article,

Lean Six Sigma Belts and Roles.

Getting Started with Lean Six Sigma

If you’re interested in Lean Six Sigma, the best way to get started is to learn how to apply it to your work.

Although the concepts of both lean and six sigma seem straightforward, it’s important to learn the correct methods used to apply them to a process.

There are many different lean six sigma training options available. We have listed our most popular lean six sigma courses below as a guideline.

When looking for the right Lean Six Sigma Course for your development, we recommend using the following steps:

Decide on your priorities

Take some time to think about your goals for both training and applying process improvement in your work.

Some examples here include:

- ability to eliminate waste from processes

- improve the quality of products / services where you work

- achieve a recognised Lean Six Sigma certification to improve your career prospects

Find a course that fits your schedule and learning style

While compiling your list of priorities, it’s useful think about how you want to learn and when you will have time to devote to training.

You will find self-led (e-learning), trainer-led (live virtual training or classroom), and blended (a combination of both) courses available from different providers.

As you research, consider which approach will work best for your schedule and give you the best learning experience.

Learn from experts

When learning about process improvement, it’s always best to learn from skilled, experienced lean six sigma professionals.

They can offer guidance and advice based on real-life experience. They understand lean and six sigma techniques from a theoretical and practical perspective.

All of our lean six sigma courses are delivered by expert, black belt certified trainers.

Get advice and recommendations

If you have friends and colleagues who have completed any lean six sigma training, ask about their experience.

When researching training providers, get in touch to ask questions and get a feel for the kind of course you will be attending. Established providers will welcome questions.

Our Lean Six Sigma Courses

We offer 3 public Lean Six Sigma Courses, with dates available throughout the year. Each focuses on meeting you wherever you are on your Lean Six Sigma path.

Our Yellow Belt course is ideal if you want to begin learning about Lean Six Sigma.

It’s a practical, 2-day course focused on giving you an introduction to the core principles of Lean. You’ll gain skills you can use immediately and a Yellow Belt certificate.

This course runs almost every month and no experience is required to attend.

Over 5 days, you achieve a strong understanding of Lean Six Sigma and learn how to actively contribute to process improvement projects in any environment.

If you have experience in process improvement and want to gain a more advanced understanding and capability, our Black Belt programme may be the perfect choice.

Over 5 short, intensive instalments we cover the skills and knowledge needed to drive continuous improvement at Black Belt level.

This programme leads to a Professional Development Black Belt and prepares you to sit the internationally recognised ASQ Certified Six Sigma Black Belt (CSSBB) exam.

What our students say about our Lean Six Sigma Courses

Here's what some of our recent participants on live virtual Lean Six Sigma courses had to say about their experience:

I had a very good experience and impression of the course. The trainer was very clear in explaining various subjects and the discussions & exercises were very productive.

This experience helps to give me a structure or a defined approach to analyse and or solve problems arising in my field of work.

Strengths of the course were theory & practice given; the virtual delivery was very good and interactive, exceeding my expectations.

Fedele

Lean Six Sigma Green Belt

The discussions and exercises were the best part of the course. Having the opportunity to hear other people’s thoughts and approaches was so helpful.

We were very fortunate to have an engaging and helpful trainer. His pace and delivery of the course content was perfect.

The tutor’s ability to engage with everyone on [live virtual training] and to give input at exactly the right time. Also, the breakout sessions were very instructive. It’s also very practical. The tutor was very patient and took the time to answer all questions. It was very much appreciated.

My experience was great as always – 3rd course completed here and hope to do more. The support is great and still providing help outside of the course is a real bonus that you do not get anywhere else.

All discussions went with ease and hard topics explained in a fashion all could understand. I was missing the real room experience like everyone in this hard time, but as a virtual course it was very informative to the point and good breaks also to break up the day.

The trainer was clearly experienced and brought his knowledge to the course. Most of us have had some exposure to Six Sigma through our careers, it was great to learn the background to the tools.

I felt expectations, and the agendas, were always clear and up-front. The course content was strong enough to stand on its own, and the exercises really helped embed the theory with practical application.

Introducing a Lean Six Sigma Culture in Your Organisation

If you would like to begin introducing a lean six sigma culture within your team or organisation, an in-company training approach is best.

This is a format of training where we deliver a programme tailored to your business to a group of participants.

Our training consultants are skilled in creating customised Lean Six Sigma training solutions that align with the unique requirements of each client.

We provide a full range of Lean Six Sigma in-company workshops and certified courses.

Use the buttons below to find out more about the kind of courses we offer or to request your in-company training quote.

More Lean Six Sigma Resources

Here are 3 ways you can learn more about Lean, Six sigma, and process improvement:

Download our PDF Guide to Lean Six Sigma

Instantly download our PDF Guide to Lean Six Sigma. This guide is handy to have while researching your next step for training and certification.

Sign up for the latest articles and guides

Sign up for our email updates and you’ll never miss a new lean six sigma article, guide, or special offer.

Browse our blog

Read through the current articles and archives on our lean six sigma blog.